Undergraduate Work in the HYPER Lab

I first started working with Jake in the HYPER Lab in 2015 and have since worked on numerous projects relating to cryogenics and hydrogen. Some of it has been course work (compressor sizing), some was club work (gas booster renovation), some of it just needed to get done (SDS collecting). But I’ve enjoyed the work and have tried to learn as much as I could. The following are short descriptions of the major projects I worked on:

- Sized compressor for medium scale hydrogen liquefaction system of refueling station.

- Reviewed variable client requirements and reported on capabilities of consumer models. Acted as liaison between the compressor team, clients, and other teams.

- Identified main concerns regarding hydrogen compressors: flammability risks, hydrogen embrittlement, oil/lubricant contamination of the gas stream.

- Conversed with manufacturers and suppliers regarding capabilities and cost.

- Renovated 2 Haskel gas boosters for hydrogen liquefaction prototype.

- Disassembled, cleaned, inspected, and reassembled 2 gas boosters.

- Purchased replacement parts worth $2000, as recommended by the manufacturer for safe usage.

- Tested stall pressure performance (up to 1500psi) and reported on abilities.

- Taught others to use the equipment and wrote a manual on usage and safety.

- Senior Design: Heat Exchanger for Hydrogen Liquefier

- Used EES and NTU method and thermal resistance to design brazed-tubes heat exchanger as requested by the client.

- Required to fit in 6” diam dewar mouth, be compatible in a hydrogen environment, and survive thermal expansion/contraction.

- Validated performance with the manufactured prototype, liquid nitrogen, flowmeter, thermocouples to 92-97% effectiveness for 2.5m length.

- Led Innovations in Sustainable Energy (ISE), the undergrad club of the lab.

- Guided team in designing vent lines and vent stack.

- Developed further EES models of nitrogen (liquefier) refrigeration capacity and compared them with heat leak rates based on thermal resistance.

- Worked with Carl Bunge in operating the Cryocatalysis Hydrogen Experiment Facility (CHEF) for testing the effectiveness of catalyzed vortex tubes for cooling with liquid hydrogen and para->ortho transition.

- Filled CHEF using hydrogen gas bottles and control manifold.

- Leak checked fittings with helium sniffer. LN2 was used to find cold leaks.

- Ran tests off written procedure, managing heaters and watching for problems.

- Built and tested calibration apparatus for platinum RTDs, including MLI shield.

- Collected Safety Data Sheets (SDS)

- Scoured lab for chemicals. Categorized some 175 chemicals found.

- Printed SDS and organized in a binder.

- Disposed of unlabeled or unneeded chemicals in accordance with WSU chemical disposal guidelines.

- Documented procedures and suggested next steps for building, maintaining, and editing SDS binder. Described process of chemical disposal.

Planetary Resources Internship

In the spring and summer of 2017, I enjoyed work as a coop with Planetary Resources in Redmond. I worked on various projects supporting their objectives, including:

- Wrote testing procedures for loading, testing, and unloading pressurant for spacecraft propulsion system and attitude control. Ran said procedures. Characterized pressurant during thrust event. Involved use of helium leak sniffer and compressed helium bottles, vacuum pump, refrigerant compressor, thermal chamber, and Arduino-controlled solenoids.

- Designed boilerplate payloads in SolidWorks for vibration testing. Drafted technical drawings for machining per ASME Y14.5 – 2009.

- Ran load analyses of bolted joints and spacecraft separation system.

- Modeled thermal properties and designed tank/piping system for supercritical xenon propellant including pressure drop in piping and tank heating needs.

- Modeled spacecraft perturbation torques for deep space mission, primarily SRP (solar radiation pressure). Developed needs of RCS (reaction control system) thrusters and reaction wheel array. Tabulated lists of commercial options for primary thruster and desaturation thrusters.

- Modeled launch vehicle interiors and component exteriors in SolidWorks for volume budget and positioning.

- Developed first-order estimate for mass and power needs of in-orbit hydrolox propellant depot. Taught basics of hydrogen properties and liquefaction.

Graduate Research

Anytime a cryogenic liquid is being stored without active cooling, heat leak causes the liquid to slowly boil off, a major source of waste. For liquid hydrogen, the boiloff rate can be decreased if conversion from parahydrogen to orthohydrogen can be utilized to cool the ullage space of the tank. Vapor temperatures of a liquid hydrogen tank can reach 50-60K or possibly higher (compared to 20-30K for the liquid, depending on pressure). Equilibrium orthohydrogen concentration increases from ~1% to upwards of 40%, and the conversion from para to ortho absorbs heat, creating a cooling effect. So, by converting some of the boiloff gas from parahydrogen to orthohydrogen, cooling is produced, which can be used to cool the remaining gas in the ullage via heat exchanger, thus reducing boiloff. My graduate research has focused on using a vortex tube as the catalytic reactor for such a system, known as a Heisenberg Vortex Tube. It has focused on computational fluid dynamics (CFD) modeling in conjunction with Carl Bunge‘s experimental testing. Some highlights include:

- Using Python code with CoolProp to tabulate parahydrogen and orthohydrogen properties for the CFD. Example code can be viewed here.

- Building a portable test stand to test vortex tubes of various sizes (at room-temperature) with LabVIEW data acquisition.

- StarCCM+ (CFD) modeling of cryogenic and room-temperature vortex tubes to match experimental performance. This includes the typical temperature separation effect of vortex tubes, as well as the para-to-ortho conversion.

- Parametric modeling of a heat exchanger in a liquid hydrogen tank’s ullage space, comparing packed-bed ionex to our surface-catalyzed vortex tube. Required length, pressure drop, and cooling power are primary outputs.

- A publication was developed from our room-temperature testing: “Experimental and Numerical Investigation of a Miniature Additively Manufactured Vortex Tube“

- My thesis is tentatively titled “Numerical and Experimental Studies on the Vortex Tube Phenomenon”

Outside the Lab

-

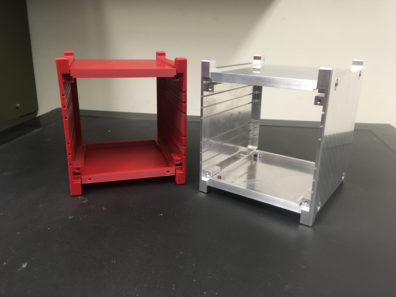

Cubesat Models: plastic additively manufactured (left), aluminum machined (right) Cougs In Space: WSU’s first CubeSat team was just starting up when I returned from Planetary. Their primary goal was to get a satellite into space and communicate with it. Their secondary goal was to germinate seeds in space, as a proof of concept. Note that I worked in this club at the same time as some of my work in the HYPER Lab.

- Led structures team in mass/volume allocations, vibration testing, and payload integration.

- Advised the team in structural concerns: outgassing, material degradation, thermal concerns, drawing design, payload leakage.

- Designed CubeSat bus in SolidWorks, produced engineering drawings for machining.

- Built test-CubeSat for an IREC launch to test vibration transmissibility.

- Cooking: I enjoy preparing food, especially baking bread.

- Brewing: I have also brewed wine, cider, mead, and ginger beer for fun.

- Gardening: At the moment of writing, I have kale, basil, and green beans growing on my apartment deck.

Contact Information

Email: gregory.wallace@wsu.edu (This is the best way to contact me. Please have a clear and concise Subject Line.)

Phone: (425) 306-3804 (I get a lot of spam phone calls, so I may not pick up. Consider texting instead of calling.)

Table of Contents

This page summarizes my experience in the lab, mostly in bullet-points. For a slightly more in depth description, I’ve also a story-formatted version of this page. If you prefer that, check it out here:

A Journey