Have you ever had a $45,000 piece of equipment show up in your facility, and thought: “I don’t remember what this is for…”? Well, I had this exact thing happen to me. I was fortunate in that the 900 pounds of equipment sitting in the shipping bay was a simple mix-up with the company delivering our equipment. Crisis averted! However, in many instances mistakes like this can lead to the loss of funds, and sometimes even jobs. The responsibility often falls to project managers to have a crystal-clear picture of the flow of parts and equipment coming in for their systems.

As the project manager and lead graduate student with the CRyogenic Accelerated Fatigue Tester (CRAFT), having a process for part procurement has been the key to avoiding headaches in the final stages of system assembly. As an engineer, a Bill of Materials (B.O.M.) has been the simplest and most informative way of handling this process.

Bill of Materials (B.O.M.) – an extensive list of raw materials, components, and assemblies required to construct, manufacture, or repair a product or service.

Simply put, a B.O.M. is a single document containing all the necessary information related to the procurement of material for a project. When I began my journey sourcing parts for CRAFT, I shot from the hip. I would bounce around ideas in my head, do some mental math, and then dump a list of parts into an excel spreadsheet. This failed attempt at a B.O.M. had no structure and gave no clear indication if the parts had even been ordered. It was no surprise that 3-months later when a pile of parts arrived, I spent too many hours sifting through orders trying to remember: “why did I order 10 KF-25 vacuum flanges”?

Hindsight is 20/20, and if I would have taken the time to develop a rigorous process for organizing my materials; life would have been much simpler. Luckily, I was recently given another chance to go through this process. In this post I will walk you through the HYPER method for part procurement, including some helpful tips along the way to make this process smoother for all parties. In the second half, HYPER’s very own lab manager Mark Parsons will discuss how this process is handled at an administrator level, and how we as engineers can help him make this task painless.

1.) Have a B.O.M. template in place that lists all the key information relevant to the part and its relationship with the system you are designing.

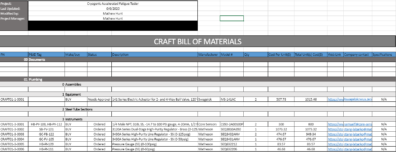

When you are adding things to a structured B.O.M., it becomes easy to simply drag and drop items into the document. The document used by the HYPER lab is seen below.

Figure 1. HYPER Lab B.O.M. Template

Each part purchased is given a unique serialized identifier that is organized by part type and subtype. These parts are then given an associated tag that references its location on the system’s Piping & Instrumentation Diagram (P&ID). Furthermore, all the relevant information that identifies the part and its manufacturer is kept on file, with accrued costs in acquiring it. Lastly, the status of the part is maintained as to keep a real-time record of the parts travel from purchasing to receiving. An example of this can be seen below:

Figure 2. Example B.O.M. for CRAFT

2.) Reach out to your colleagues for relevant information.

I have found it helpful to lean on the gracious advice of those that have come before me. Be respectful and acknowledge that they are busy, but the experience they have can push you in the right direction when searching for part manufacturers, device types, etc… Furthermore, they often will have a connection with the companies they have worked with or ordered parts through. This often helps expedite the quoting process as you can quickly introduce yourself and their own relationship with the lab, avoiding the tidal wave of quotes being sifted through by a computer. Be sure to save this contact information. I have plugged this information right into the CRAFT B.O.M., so that in the future I can reference this document or pass this information on to those who come after me.

3.) Understand how the cost of your purchase effects the levels of administrative approval.

At Washington State University, the work involved in purchasing parts or equipment often has a monetary threshold. Depending on the price, this can often add on to the lead-time expected for parts to arrive in your facility. For example, at WSU there are three monetary ranges to consider when ordering parts:

- Simple purchases (< $2,500): Simple purchases are the most common purchases made in HYPER and usually amount to simple parts, fasteners, and sensors. These purchases require no extra paperwork, meaning that only approval of the purchasing manager is necessary.

- Tax-exemption (> $2,500): When making purchases over $2,500, WSU’s purchasing office requires the submission of a tax-exemption form (except for consumable items). This extra level of approval requires signatures from the principal investigator of the lab, the director of the department, and the dean of the department. Often tax-exemption forms are required for pieces of equipment or machinery. For example, CRAFT uses a turbo pump on its vacuum chamber to reach suitable vacuum levels. This system was over $2,500, requiring a tax-exemption form. If you are bulk ordering lots of individual cheaper parts, I recommend splitting the order into multiple smaller quotes or submitting the purchase as numerous simple purchases. This will often allow you to avoid the need for a tax-exemption form, making the purchasing process faster, and easier.

- Formal bidding (> $10,000): Unless unavoidable, I highly recommend keeping purchases well below the third threshold. More often than not, purchases over $10,000 are for very expensive pieces of equipment. For example, CRAFT utilizes a load frame to test material properties and this system was well over $100,000. This was unavoidable and required the university to go out for formal bidding. This tedious process involved putting together a detailed list of the specifications required of the equipment to reach the system needs being designed around. This is then provided to the purchasing office. You will then recommend manufacturers you are interested in that can meet the listed specifications. The purchasing office will then go out and request a quote from the various manufactures and return those to you. It is then up to you, and 2 others to review the quotes and grade them officially. The graded workbook is then returned to the purchasing office, who will review it before accepting the purchase. For CRAFT, this process took about 6 weeks with an added lead time of 14 weeks to manufacture the load frame. There is one way to get around this process, however. If the piece of equipment is under $100,000 but greater than $10,000 you can submit what is known as a sole source purchase. A sole source purchase is a document that indicates that the piece of technology you are interested in can be sourced from only one manufacturer, or perhaps the specific deal you are interested in is provided by only one company. If this is not possible, then the purchasing office may require you to find a more cost affordable option that meets your needs.

From an engineer’s perspective, these tips and tricks are the best ways I have found to navigate purchasing parts and equipment for a system. There is however, a second half to this process and for that I would like to introduce Mark Parsons. Mark Parsons is HYPER’s lab manager and lead purchasing expert for the facility. Mark, what recommendations do you have that could shed light on making the purchasing process more efficient?

Mark’s Take

Making purchases, however large or small, can be a sticky process in the context of the state government. There are rules, regulations, contracts, auditing, records, along with enough acronyms (BPPM’s, SPPM’s, SOW’s, SOP’s to name a few) to bring you to your knees in bureaucratic agony. It is a difficult landscape to navigate, even for me, and I have been doing this for 12 years. This complexity, described handily by Mathew, can make people feel fearful or even angry with the process. What can happen is that we can start to view our administrators as roadblocks or obstructions or maybe even something with horns and a pointy tail.

While we cannot circumvent the process, we can certainly make it smoother. This is where I come in, your friendly neighborhood purchasing agent. My job is to help you navigate and execute the purchasing process. If making purchases, especially large purchases, seems daunting, know that I am here to guide you and not stand in your way. At least that is how it should be.

Reading this might make you think, “wow, that sounds like a very symbiotic professional relationship. What could possibly go wrong?”

Probably the biggest hurdles in the purchaser-requester relationship are conflicting priorities. The requestor (you) is trying to accomplish a task and you need a part or service to do so. The purchaser (me) is trying to make sure that proper procedure is followed when obtaining said part or service. These priorities are often at odds with one another especially when time is an issue. Fortunately, you can avoid many pitfalls by employing the same cornerstone of any successful relationship: communication.

First off, I cannot emphasize this enough; communicate with your purchaser. Let them know what your needs are and give them a clear picture of what expectations you may have. Likewise, invite them to tell you what they expect from you and what procedures you should follow to keep the process smooth. Remember, every single purchase requires a time-consuming series of steps and procedures that every state purchaser must follow. This is mostly invisible to the end user, so it is important to keep this in mind. A lot of headaches can be avoided just through a few verbal or email exchanges.

Secondly, involve your purchaser often. An experienced purchasing agent has a wealth of knowledge to help you. We have connections with vendors and related logistical information to aid in informing your buying decision. Part of our job is also to keep tabs on how our vendors perform. We usually know who has better fill rates and turnaround times, and if we do not, we know how to find out. Also, we have connections within the university that we can pull on to help with other situations that can arise. Need your order sent to an alternative location? We know who to call. Your new piece of equipment needs special handling? We know a guy.

Lastly, involve your purchaser early. This mostly applies to large purchases over $2500. This is where the biggest problems can surface. Mathew spoke briefly about how certain dollar thresholds add lead time to your purchases. Allow me to be more specific. A tax-exempt purchase (non-consumable equipment over $2500) can take anywhere from 2-6 weeks to process. A sole source purchase (over $10K from a specific vendor) is about the same if not longer. If your request must go out for bid you are looking at a minimum of 4-8 weeks (I have seen the process take as long as 6 months, but this is rare.) Do not make the mistake of submitting a purchase request for $12K two weeks before you need it. The moment you know you are going to spend a significant amount of money you need to involve your purchaser as soon as possible. They can help give you an idea of how much lead time to expect and they can assist you in preparing the proper documentation to submit to central administration for processing.

Of course, mistakes will happen. PO’s will get mislaid. Emails will get sent to the junk folder. Someone will get sick or go on an extended vacation. However, if you prepare well and follow these guidelines you will be setup for success in the long run.