CRyogenic Accelerated Fatigue Testing (CRAFT)

The CRyogenic Accelerated Fatigue Tester (CRAFT), is the first fully electric load frame capable of fatigue testing polymeric materials in a liquefied hydrogen environment. Designed by Ph.D. student Mathew Hunt, CRAFT was made to give insight to the cryogenic material world.

At that point, data on material properties at cryogenic temperatures, below 123 K (−150 °C, −238 °F), was sparse. CRAFT allows for the tensile, compressive, and fatigue testing of polymer composites in a liquid nitrogen (77 K) or liquid hydrogen (20 K) bath. CRAFT was built and became operational in the Summer of 2020.

Now completed, the HYPER Lab does offer its services for interested parties for a variety of materials. If you or your company are interested, please contact Dr. Jacob Leachman at jacob.leachman@wsu.edu.

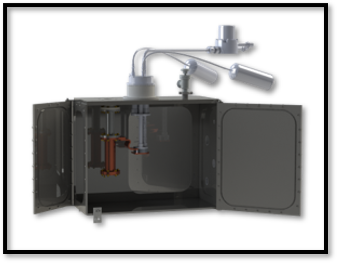

CRAFT uses an MTS Acumen 12 load frame to achieve the force and frequency seen below. To achieve vacuum, CRAFT uses a two-stage vacuum system. First, an Agilent Varian IDP-07 Dry Scroll Vacuum Pump to drop the pressure to 2.5 Pa, and then an Agilent Turbo-V 81 M Turbomolecular Pump to bring the pressure down to ~10-5 Pa. For cooling, a Cryomech CP 1010 Helium Compressor combined with a PT415 Cryocooler are utilized.

CRAFT uses a steel body vacuum chamber to house the testing environment. The testing chamber can fill with up to .57 L of liquid. A custom bellows seal for translational movement is used to allow for the passage of the extension rod. CRAFT uses a thermal strap rather than a thermal busbar to move heat out of the system.

Table of Contents

System and Test Specifications

Load Frame:

- Static Force Range………………………………………………………………………Up to 8.5 kN (1910 lbf)

- Dynamic Force Range…………………………………………………………………Up to 12 kN (2697 lbf)

- Frequency Range………………………………………………………………………..Up to 100 Hz

- Minimum Temperature (based on cryocooler capabilities)…………..4 K (-269 °C, -452 °F)

- Minimum Pressure………………………………………………………………………~ 10^(-5) Pa

- Fill Tank Volume…………………………………………………………………………..0.57 L

Test Cell Dimensions :

- Radius…………………………………………………………………………………………1.125″

- Height………………………………………………………………………………………….9″

- Volume………………………………………………………………………………………..35.78″ (0.57 liters)

CRAFT is capable of accommodating a variety of specimen dimensions. At this time, the HYPER Lab is interested in testing coupons of the following dimensions, adapted from ASTM D638 Type V tensile specimens.

Coupon Dimensions (Note: Dimensions are in inches):

2018 – 2021: Mathew Hunt: Designing CRAFT

Past Project Workings:

Mathew was the Project Manager and graduate research assistant in charge of CRAFT during its building and testing period between 2018 to Spring 2021. Mathew’s main interest with CRAFT was in the investigation of the material properties for customized polymer nanocomposites used in cryogenic systems.

Background:

Mathew is a Puget Sound native who joined the HYPER lab in 2016 as an undergraduate to assist in the testing of 3D printed thermoplastics. He has since gone to work for Maxar in Silicon Valley. Maxar makes satellites and propulsion systems.

For more information on Mathew Hunt, follow this link here.

Research Highlights

Research Grant: US Army

Mathew Hunt’s Graduate Student Showcase:

2020 – 2022: Reece Adams: Mechanical Data Acquisition

Past Project Workings:

Reece Adams was a former Project Manager and graduate research assistant in charge of CRAFT. There exists little information on the cryogenic mechanical properties of composites produced by means of additive manufacturing. Reece’s master’s thesis targeted the mechanical and thermal optimization of additively manufactured materials in cryogenic applications. Through his research, he was able to develop a mechanical characterization of additively manufactured AlSi10Mg, A6061-RAM2, and PA840-GSL at 20K. These materials are currently being used in our heat exchanger and hydrogen tanks, so developing a characterization of these materials is pertinent to the work within the lab. Reece began to fill the void of understanding that exists with the application and optimization of additively manufactured materials in cryogenic environments. Reece has since transitioned to his role as Project Engineer at Janicki Industries in western Washington.

Background:

Reece was born and raised in Spokane and joined the lab as an undergraduate researcher in 2019. Initially, Reece focused on performing gelbo flex tests on thin polymer films in liquid nitrogen for determining the feasibility of employing those materials in liquid cryogen fuel storage. Reece was also closely involved on the development of CRAFT with Mathew Hunt and transitioned to team lead after Mathew’s graduation.

For more information on Reece Adams, follow this link here.

Research Highlights

Research Grant: US Army